Inside the Audi Sport future labs

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

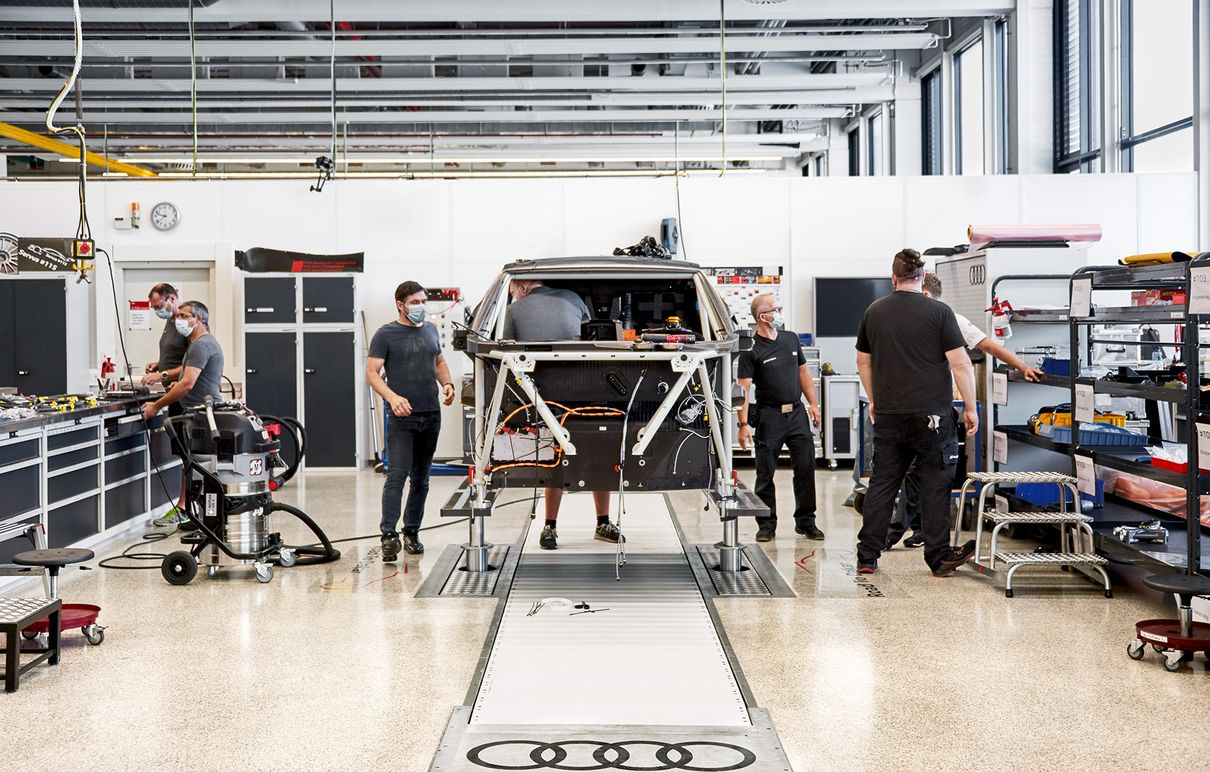

Silence, an occasional brief exchange of words, then silence again. In the clean, bright workshop, the men intently focused on the elevated cage that will soon become the driver’s cell of a rally car need few words to understand each other. Racing legend Carlos Sainz sits motionless behind the steering wheel. The area underneath and behind him is being filled with foam; when the foam hardens, the result will be a driver’s seat perfectly molded to Sainz’s body. The technicians and engineers must get every detail right—too much hesitation or one clumsy move and the process will have to start all over again. Seat fitting is a key stage in a special project such as this. Here in Neuburg an der Donau, the Audi RS Q e-tron¹ is being developed to hold its own in the Dakar Rally in January 2022 with an electrified drive concept. Sainz is one of the drivers for the three Audi Sport teams competing. Three vehicles, each with an Audi driver and co-driver, will tough it out in the desert for two weeks with a drive system that combines an electric drive train with an energy converter system comprising a TFSI engine and generator—a challenging concept based on an ambitious plan.

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

The project is ambitious through and through, starting with the timing: It all began in the summer of 2020. To ensure adequate time for the requisite tests before Dakar, vehicle testing had to begin by summer 2021. That meant there were fewer than twelve months to develop the vehicle—a flat-out sprint from conception to construction, design and assembly, and all under pandemic conditions. The challenge was met by a team of developers and technicians from Audi Sport and its partner Q Motorsport, which brings with it a wealth of experience, good contacts and, not least, numerous successes at Dakar. “The project was and still is a challenge for the entire team,” says Stefan Dreyer, Head of Development at Audi Sport. How to overcome it? “With the right mindset: with courage, stability, perseverance and ambition.”

“

We need to be prepared for every eventuality. At Dakar, you never know what to expect.”

And armed with experience. Neuburg has experience to spare, as clearly demonstrated by the floor-to-ceiling trophy cabinet in the foyer alone. Audi Sport has written racing history—in the Le Mans endurance race, the Nürburgring-Nordschleife, the DTM, Formula E and in rally racing. In the early 1980s, an innovative technology made its debut in rally racing—the quattro drive system. Now Audi is making a return to rally and to what is probably the toughest competition of all, the Dakar Rally with its pioneering drive concept. The team is also able to draw on earlier developments: The Audi RS Q e-tron¹ uses a total of three electric motors from Formula E as well as a TFSI engine from the DTM, which were combined for the Dakar.

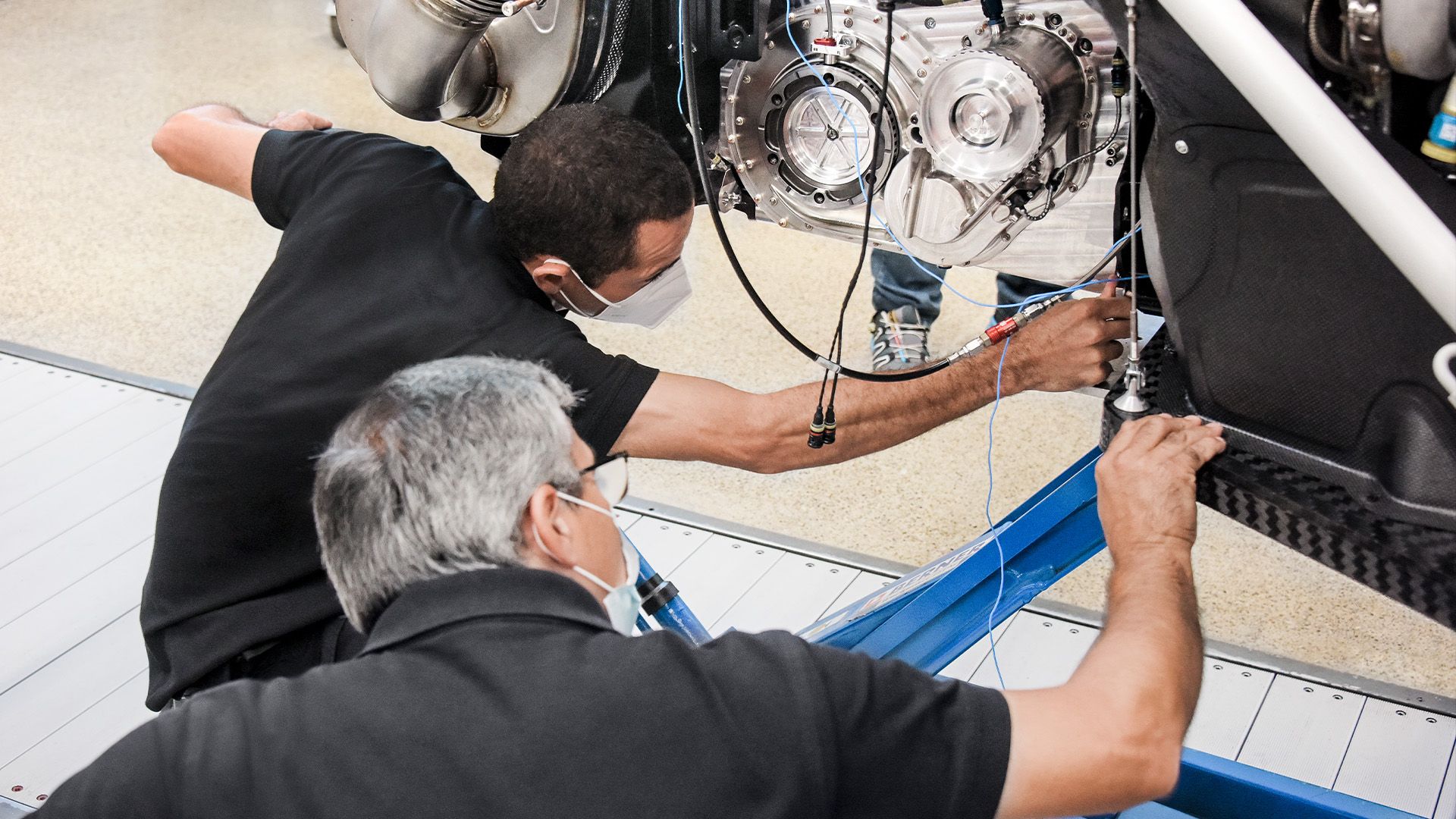

The success of the development sprint is also down to the Neuburg complex itself. It is home to the Motorsport center of excellence that includes the works and customer racing department, where the technical development team also tests driving assistance and safety systems. The site accommodates around 400 employees. It also houses test tracks open to customers who can try out new models such as the new Audi RS e-tron GT2 on the circuits as part of the Audi driving experience. The 47-hectare site is the beating heart of Audi Motorsport, where experience flows from one area to the next. Alongside a well-oiled team, the infrastructure boasts equipment ranging from engine test rigs to simulators and test tracks. Working together here, the Dakar team has reached important milestones. “Seeing the car emerge in the workshop piece by piece, everyone working hand in hand, communicating without words—that’s when you know it’s all coming together,” says Dreyer. Similarly, the start of testing is another memorable moment. The vehicle is considered extremely complex. The moment when everything fits together like a puzzle and the car drives its first metres is all the more special.

Audi RS e-tron GT: Power consumption (combined) in kWh/100 km: 21.1–18.4CO₂ emissions (combined) in g/km: 0CO₂ emission class: A

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

Audi RS e-tron GT: Power consumption (combined) in kWh/100 km: 21.1–18.4CO₂ emissions (combined) in g/km: 0CO₂ emission class: A

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

“

How to overcome the Rally Dakar? With the right mindset: with courage, stability, perseverance and ambition.”

For all the spine-tingling moments, the Audi RS Q e-tron¹ still has a way to go. That’s because, just like the development phase, testing also poses a challenge. “Dakar is like a treasure chest - you never know what you might find,” says Dreyer. “We need to be prepared for every eventuality.” That is why the vehicles undergo rigorous testing at Audi Sport, under real-life conditions as well as in the workshops. High-tech solutions are used alongside craftsmanship, as can be seen in the “start-up room”. Body parts of the Audi RS Q e-tron¹ are spread out on the floor, the driver’s cab has been put in position. Using the latest technology and their most important tool - their hearing - two technicians check the cabin material from every angle for tiny air pockets that might create weak points. They tap the material centimeter by centimeter, looking for any variation in the sound, which could indicate the slightest inaccuracy in the workmanship. Such flaws could have dire consequences at the rally. The individual components must be able to withstand the stresses of the harsh desert road conditions. And time is running out. The team only has about five months of testing time left before the Dakar begins - a two-week race involving long daily stages, rain, heat, dust and extreme demands on materials and crew alike. A veritable challenge for a new vehicle concept. But that is exactly what Audi Sport was looking for, according to Dreyer. Ultimately, the desire to participate was sparked by one question: What will the efficient, high-performance, long-range drive train look like in tomorrow’s motorsports? Audi Sport’s answer is the energy converter concept being used in the Audi RS Q e-tron¹ for the first time - but not for the last if all goes to plan. According to Dreyer: “The concept represents a new direction in our motorsport strategy. It can be used in any motorsport application and is scalable and future-proof, since new technologies can also be incorporated as in modular systems. With its many challenges, the Dakar Rally is the perfect test lab for the concept. With all of the freedom and opportunities it offers, the rally is considered to be a perfect platform to demonstrate Vorsprung durch Technik today. This is especially true since the event organiser ASO is making a conscious move toward alternative drive concepts.

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

The Audi Sport team is going to Dakar with a mission: to forge new paths, prove that it’s possible and show that electric-powered vehicles are worthy competitors. The entire team is working hard to achieve that ambition: from the technicians intently focused on creating the perfect seat for driver and co-driver and identifying potential problems by sound, to the drivers themselves who are training to ensure they are physically and mentally fit for the challenges of Dakar. Everything - each individual discipline and how they interact - needs to be spot on. The Four Rings’ participation in Dakar is attracting a lot of interest and the world of motorsports is watching keenly. What the world will see when it looks at the Audi RS Q e-tron¹ is Audi at its purest, especially when it comes to design. Consequently, design played a far greater role in the vehicle’s development than is otherwise the case in motorsport. Many details are reminiscent of or echo the design of production vehicles. This also reflects the project’s aim of extending its charismatic reach. Internally, it is geared to helping further promote electrification - of motor racing and of series development. Both are to benefit from the knowledge gained in the Saudi Arabian desert. One thing is certain: Dakar 2022 is only the first step. The concept is to be refined further. “Our commitment is an investment in the future, based on the maxim: If you stop getting better, you stop being good,” says Dreyer. “This idea spurs us on - we aim to keep on reinventing ourselves to ensure our success.”

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

¹This vehicle is the Dakar Rally vehicle that is not available as a production model.

A look behind the scenes at the Audi Sport future labs